6 Typical issues and solutions when processing PE-RT pipes

Due to operation or other reasons, PERT pipe producing process is prone to the following 6 typical issues. Here are the details and solutions.

1. Bubbles in pipe wall

Possible reasons and solution:

※The PE-RT pipe production line’s vacuum at the vacuum vent is too low or blocked. Check the working condition of the pump, whether the pipeline is blocked or not.

※Occur chemical decomposed because of the over-heated die head and moulds. Lower the temperture is workable.

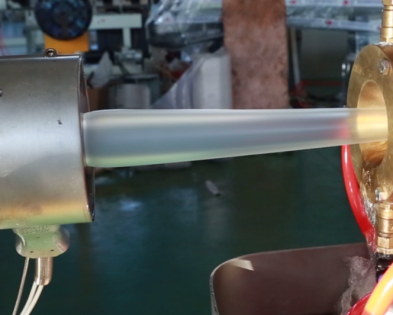

![@%3`@@QN5V`1QL`Q]VR3A8U.png](/UEditor/../../Upload/20200706051823201.png)

2. Tan-yellow stripes or color spots in pipe surface

※There are dead corners or depressions in the mold or the spreader, which may cause stagnation and paste and cause partial decomposition stripes. And the moulds partial decomposition and dead corners increase the friction with pipe surface, then stripes will be formed. Need clean up the mould.

※Uneven mixing or impurities in the material can cause partial decomposition and form surface color spot.In order to confirm the specific reason,pls improve the mixing technique or replace the problem raw materials.

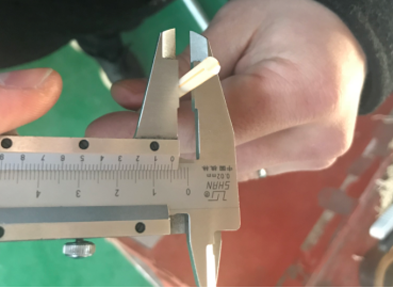

![03UO8MQ4BXAN(TI}(9U]0O7.png](/UEditor/../../Upload/20200706051838232.png)

3. Surface discoloration

※Over-heated barrel or die head makes the raw material decomposed. Then, cool down them.

※The stability of the material is not enough and decomposition occurs. It’s necessary to check what causes the insufficient stability, the PVC resin or stabilizers.Then,replace the resin or stabilizer, or increase the number of stabilizers.

※The temperature instrument not work. Over heating causes decomposition. Then calibrating and do maintenance of instruments.

4. Surface Lack of luster

※The die mouth temperature is too low. Increase the die mouth temperature,and the amount of the ACR to improve the surface shear force.The bright ACR additives can significantly improve the surface finish even at the lower temperature.

※The die mouth temperature is too high or inner surface finish poor. Then, low down the temperature and decrease the roughness.

5. Rough inner surface

※Probably reason: mandrel temperature too low. Increase the mandrel temperature or add processing additives. Low temperature causes poor plasticization, low processing properties in inner surface at the mandrel part.

6. Uneven pipe thickness

※Uneven die head temperature, and the extruding output is not uniform in each pipe degree. Need to check the heating ring, and check whether the screw has pulsation phenomenon.

※Unstable haul-off speed. Check and repair the haul-off machine.

In case you have any processing problems, welcome to leave your messages.