Red PEX pipe carriers hot water

Blue PEX pipe carries cold water

While PEX pipe can be used for either hot or cold water

Gray PEX pipe, like white, can be used for either hot or cold water)

FANTASTIC FLEXIBILITY

Traditional copper and galvanized steel water systems feature main lines and a series of smaller branch lines that to each fixture. Each branch that attached to the main lines requires a separate connection. PEX has a distinct advantage over these materials because of its flexibiliblity, which allows one end of PEX pipe to connect to a PEX manifold (the main water control system), and then wind through walls and floors-uninterrupated.all the way to an individual fixture. Called “homerun” plumbing, by using a single length of PEX for each hot and cold water supply fixture in your home, it eliminates the risk of leaks at multiple connection sites.

Benefits and Drawbacks

Beyond flexibility, PEX has other advantages-and two main considerations.

PROS

Installing PEX does not require soldering as does copper and galvanized steel

PEX expands, making it more resistant to freeze-cracking than either copper or steel.

PEX does not corrode, which can happen with both copper and steel pipes, leading to leaks and contamination of the water supply.

Water flows silently through PEX, eliminating the “Water hammer” noise associated with metal piping.

Color-coding (red and blue) make it simple to distinguish hot and cold supply lines.

PEX can be connected to existing metal supply lines with the correct fittings.

CONS

PEX is not suitable for outdoor use. Ultraviolet rays cause PEX to break down quickly-tubing left outdoors can harden and crack within a couple of months.

PEX cannot currently be recycled, because it does not melt as other recyclable plastics do. With the popularity of PEX rising, however, the demand for a way to recycled it will also likely rise.

Though installation is DIY-friendly, working with PEX requires special connectors and tools.

LABEL LINGO

The different type of PEX are distinguished by the manufacturing process used to make the tubing. When shopping for PEX, you may notice rolls labeled with either an A, B, or C designation. Choose the tubing best suited to your needs:

PEXa is manufactured by raw extruder using peroxide for crosslinking. This type of PEX is the most flexible of three types and is suitable for use in all home water-supply plumbing needs. It expands to the greatest degree when subjected to freezing water, so it’s the most resistant to racking in frigid temperatures. It’s easy to work with but it’s more expensive than B or C. Other than flexibility, PEX-a has no significant benefit over PEX-b.

PEX-b is manufactured by screw extruder using silicon with moisture-cure method for cross linking (team cross-linking). PEXb is slightly stiffer than PEX-a, and has a distinct coil “memory” that makes the tubing want to return to its original coiled state. The coil memory, however, is not a hurdle to installation, and PEX-b is often the tubing of choice for residential plumbing because it also expands to resist cracking when water freezes ubt is less expensive than PEXa. PEX-b also features an increased resistance to chlorine, making it a good choice in areas where water is highly chlorinated.

PEX-c is manufactured via an irradiation method. Because it’s the stiffest version, PEX-c is the most difficult to work with; this stiffness also makes it most prone to kinking, as well as susceptible to cracking when water freezes. These undesirable traits make PEX-C best suited for short repaires where bending around sharp corners isn’t necessary.

KAIDE company provide different PEX pipe making machines, like PEXa pipes, PEXb pipes, PEX-AL-PEX with aluminum pipes, and PEX with anti-UV layer pipes.

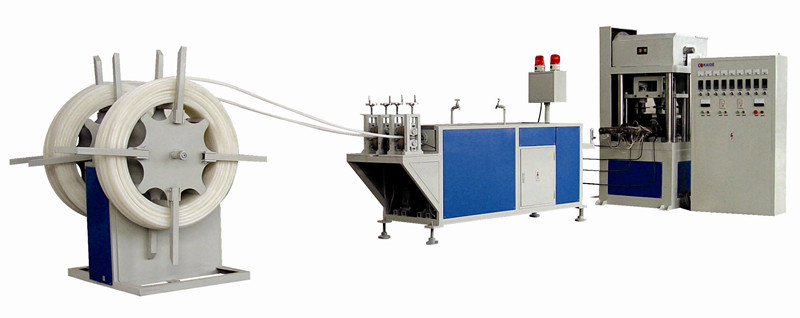

Ram extruder for PEXa pipe making; cross-linking process is down on line, no extra tools or process required for cross-linking.

Screw extruder for PEXb pipe making; Cross-linking process is done off line with a steam container

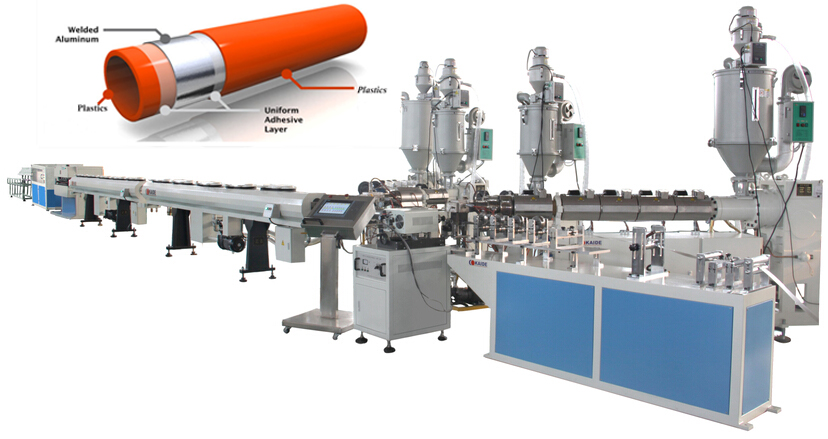

Multi-layer PEX-AL-PEX pipe making machine.

Multilayer PEX EVOH oxygen barrier pipe making machine

Contact us now to get PEX pipe making machine details!