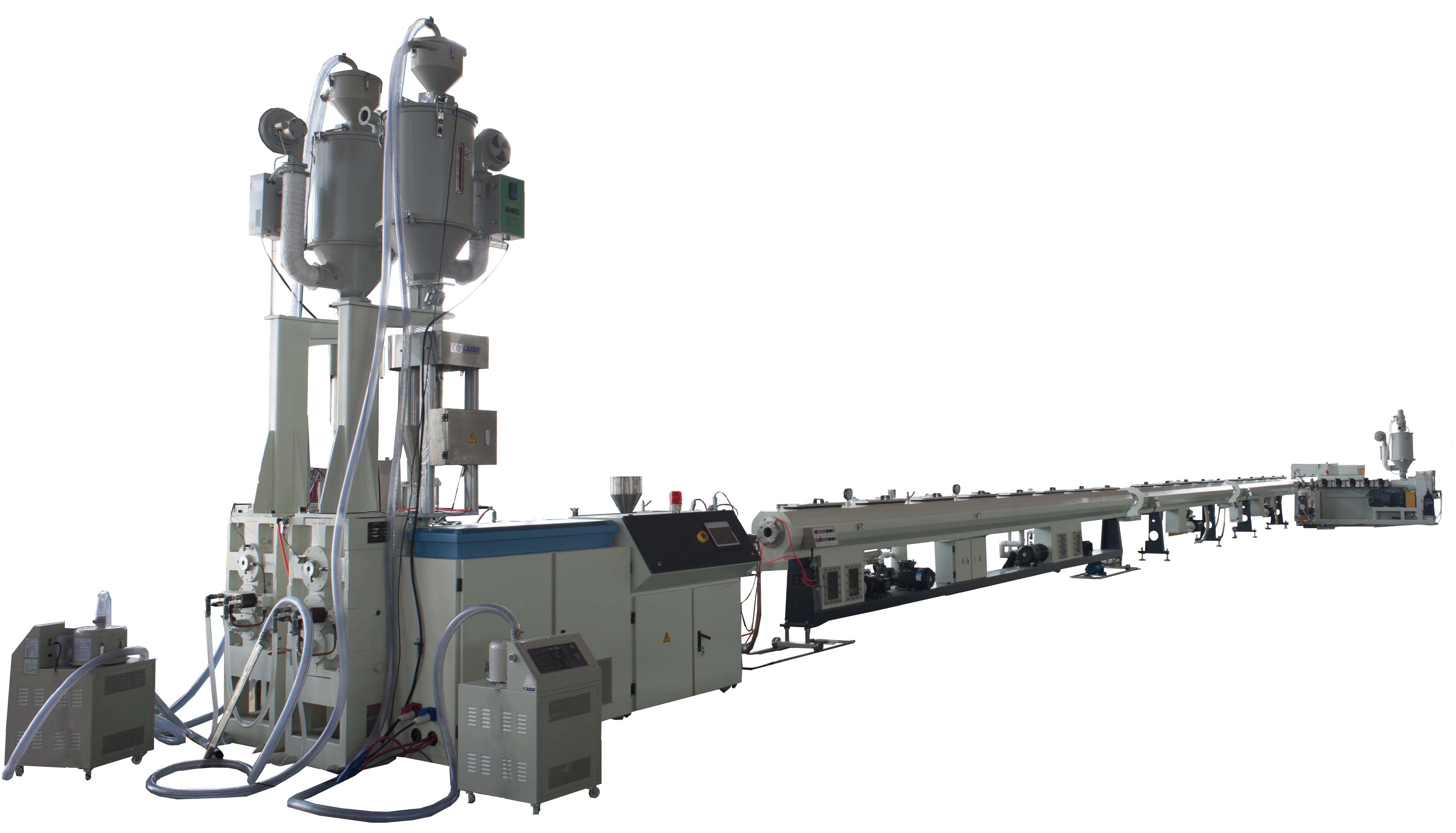

The glassfiber ppr pipe making machine adopts the specialized high efficient wear-resistant extruderfor glass fiber reinforced plastic material, which ensures high speed extrusion and guarantee the long service life of extruder.

Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

SJ-60 | Ф60/65/65 | 36/33/33:1 | ф20-63(110)mm | 20m/min | 165KW |

SJ-65 | ф65/65/65 | 33/33/33:1 | ф20-63(110)mm | 15m/min | 119KW |

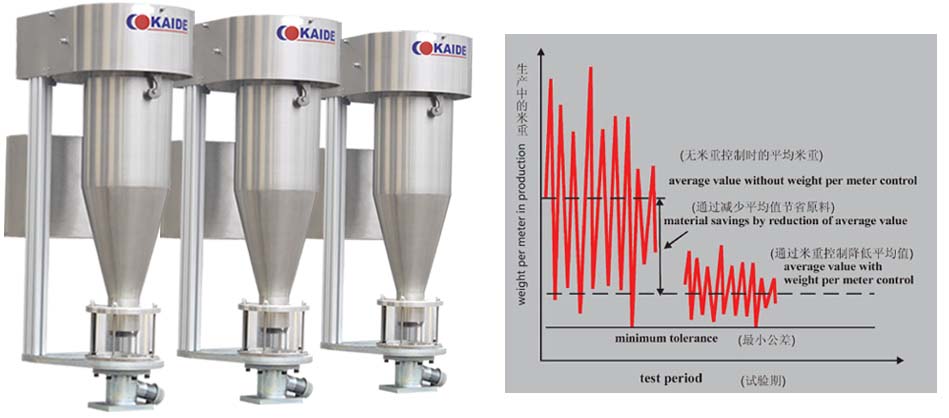

● Gravimeter System

High precise Gravimeter control system of is applied in this glassfiber PPR pipe production line.

◎It is used for measuring & calculating and precise control of pipe weight permeter and its extrusion output, to realize the constancy of pipe weight.

◎The application of this system can shorten the start-up time, improve the produced pipe quality, and save raw material.

● Co-extrusion die head

◎Patented specially designed adjustable co-extrusion die head, can ensure even thickness of three layers,

◎Each layer thickness can be adjusted freely; no need to adjust the extruder’s rotating speed.

● Haul-off machine

◎ The haul-off machine adopts structure of high speed multi-group roller clamping type.

◎ Completely overcomes the vibration & skip problems in the traditional mode, ensuring high-speed stable pulling.

● PE Anti-UV Layer Extruder

◎ PE Layer thickness about 0.6mm-0.8mm, this PE Anti-UV layer extruder is specially designed for PE raw materials extruded.

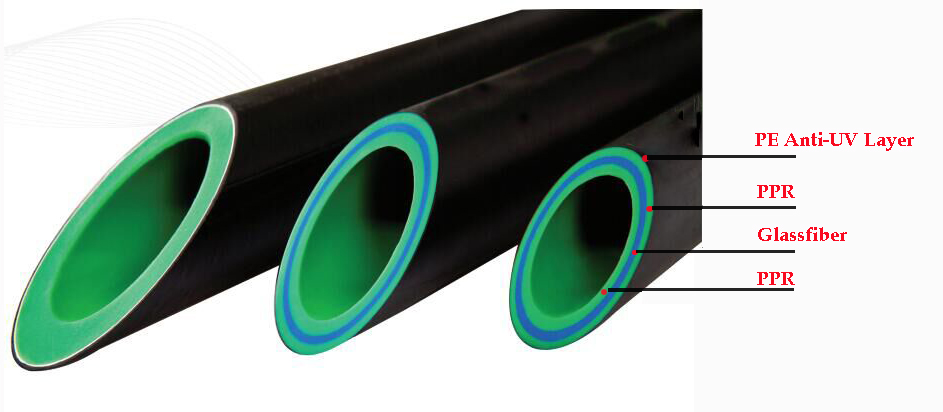

● Manufactured Pipe

① The outer layer is PE Anti-UV layer with thickness 0.6mm-0.8mm

② The second layer is PPR layer

③ The third layer is glassfiber layer

④ The forth layer is PPR layer .

This special 4 layers fiber reinforced PPR pipe is mostly suitable for high temperature hot water transporting in outdoors , and the PE Anti-UV layer can lengthen the lifespan of the pipe, resistance the ultraviolet rays, with wide application in the areas with strong sunlight and solarization.

4 Layers Glassfiber PPR Composite (PE Anti-UV )Pipe Production Line.pdf

4 Layers Glassfiber PPR Composite (PE Anti-UV )Pipe Production Line.pdf