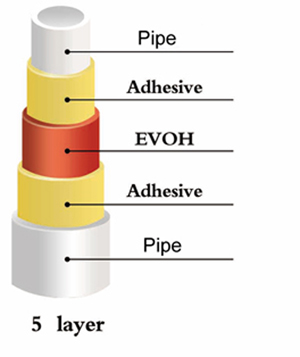

The 5 layers composite EVOH pipe production line adopts advanced extrusion technology with serveral extruders and co-extrusion die head moulds, which makes the compoiste pipe bond firmly with precise size. The screw and barrel are specially designed according to the property of EVOH resin. It is suitable for stable extrusion of high melting pressure of oxygen barrier resin.

Line Model

| Screw Diameter

| Production Scope

| Production Speed

| EVOH Thickness

|

KDZY-65 | Ф65mm | Ф16-32mm | 15m/min | 0.15mm |

KDZY-60 | Ф60mm | ф16-63mm | 35m/min | 0.15mm |

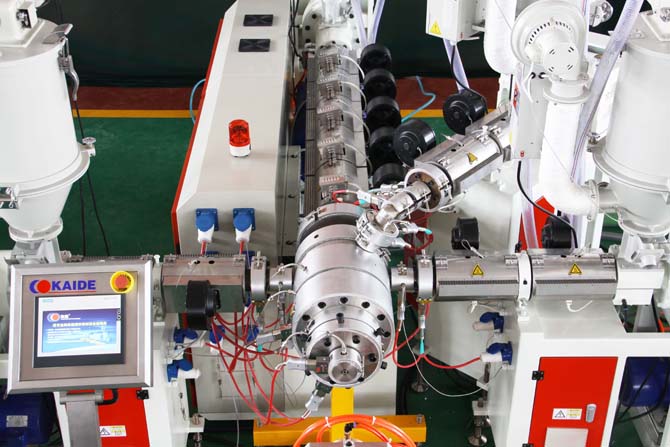

● 5 layers EVOH Multilayer Die Head

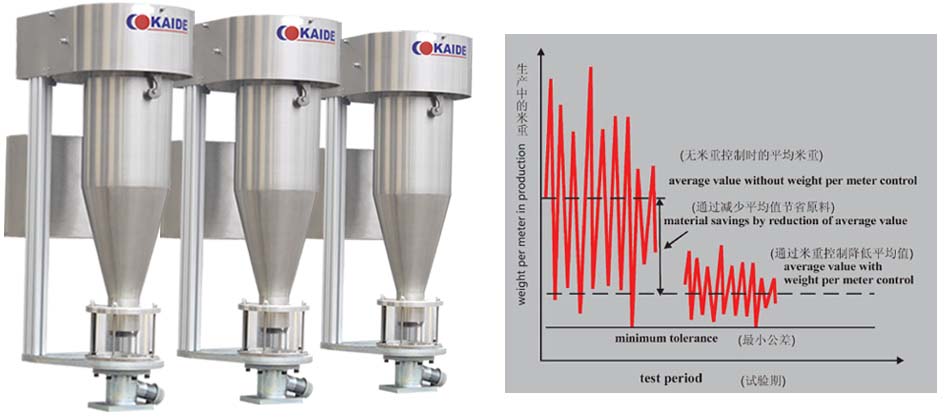

● Gravimeter system

High precise Gravimeter control system of is applied in this EVOH pipe production line.

◎ It is used for measuring & calculating and precise control of pipe weight per meter and its extrusion output, to realize the constancy of pipe weight.

◎ This application of this system can shorten the start up time, improve the produced pipe quality, and save raw materials.

● Manufactured pipe

Advantages of EVOH oxygen barrier composite pipe:

◎Excellent non-permeability and scent preservation, good anti ultraviolet ray and other radiations, which greatly enlarge the pipe’s lifespan and effectively avoid breeding of bacteria inner pipes.

◎This kind of pipe will have a good market prospects and wide application in the current and future time.

● Production line series

The EVOH composite Pipe Machine can produce single layer pipe, and also three-layer or five-layer,Such as :

◎ PB/EVOH pipe production line,

◎ PE-RT /EVOH pipe production line,

◎ PE-Xa/EVOH pipe production line,

◎ PE-Xb/EVOHpipe production ,

◎ PP-R/EVOH pipe production line,

◎ PA/EVOH pipe line.