Home>Product>Melt Blown Non-woven Fabric Production Line

Melt Blown Nonwovens Production Line

Melt Blown Nonwovens Production Line

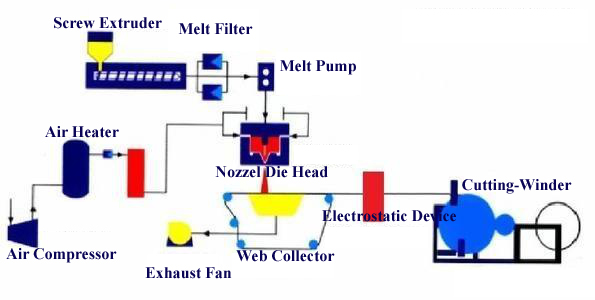

This production line is used to produce PP melt blown Non-wovens Fabric, which are widely used both in medical field. The processing technic is as below:

The specialized PP raw materials are feeded by auto Loader in to the Extruder, through the screw rotating, the PP raw materials is sufficiently melting in the barrel, The Air blower blows the air into the Air Heater. The heated air will blow the liquid melted Polypropylene materials (PP) through the Nozzel Die Heads, which manufactured hundreds of small holes in the mold. Then the threaded materials reach to the collector, and finally formed to finished Non-wovens fabric. This flow chart can well-explain:

4 Extruder Model

Extruder Series: SJ45/25, SJ45/30, SJ50/33, SJ65/30, SJ65/33

Control Mode:Siemens PLC Control or Omron Instrument Control

Frequency Inverter: ABB Brand

Electrics Components: Schneider

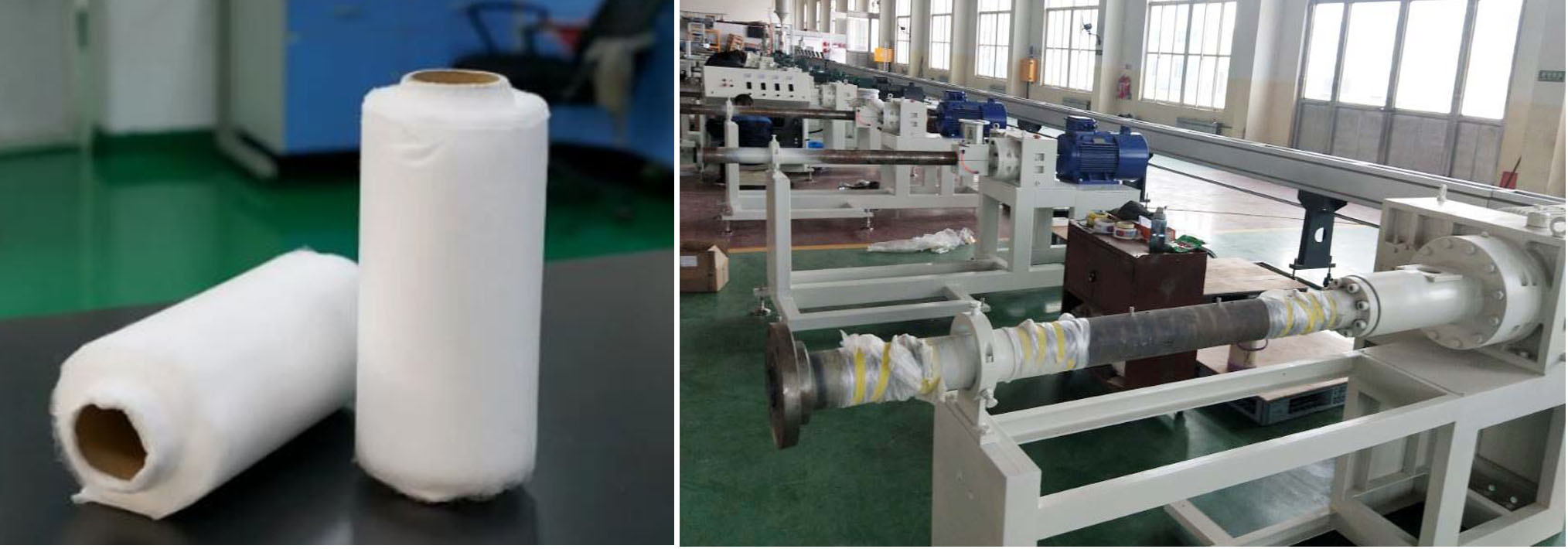

4 Melt Blown Non-wovens Fabric Winder

Fuction: Cloth Rolling, cloth measuring;

Adjustable speed: Selection of the Governor, flexible cloth speed control;

Length measurement: A note yards (meter counters equipped), which can measure the length of the cloth;

Flexible and easy to operate;

Stable and durable: the reasonable design of the structure, using high-quality components,durable.

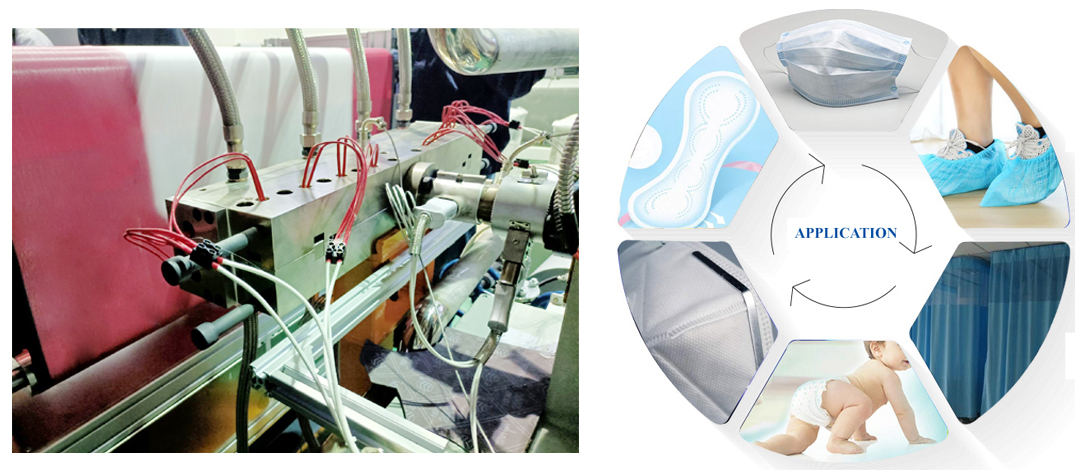

4 Application of Melt Blown Non-wovens Fabric

Hygienic Matierals: Baby Diapers, Sanitary Napkins, etc

Medical Products: Surgery Face Mask, Disposable face Mask, Surgey use cloth Curtain, Show Cover etc.

Packing Materials: Shopping Bag, Clothing Packing

Houseware: Spring Cloth, Seat supplies

Other Application: Protection Clothing.