The PB Pipe Production Line has adopted new designed five-section type screw, which is special for PB material processing,ensuring the high speed PB pipe production.

Line Model | Screw Diameter | L/D | Production Scope | Output | Nominal Power | L×W×H |

KDPB-65 | ф65mm | 33:1 | ф20-32mm | 90kgs/h | 64KW | 30×2×3 |

KDPB-60 | Ф60mm | 36:1 | ф20-63mm | 180kgs/h | 95KW | 32×2×3 |

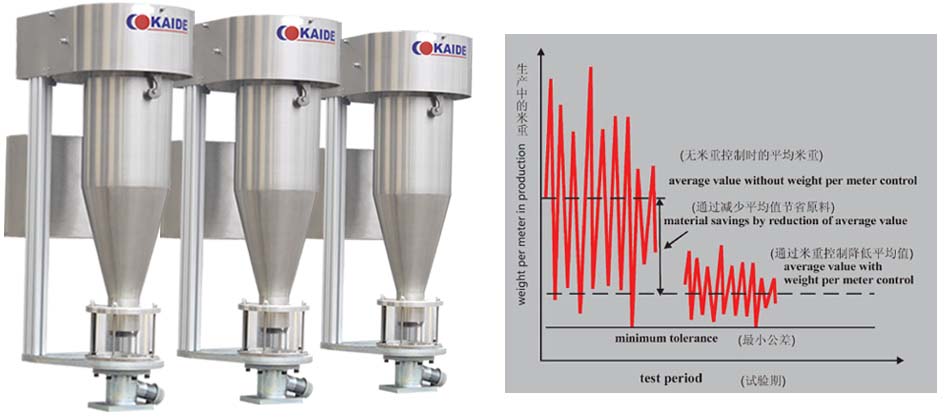

●Gravimeter System

High precise Gravimeter control system of is applied in this PB pipe production line.

◎It is used for measuring & calculating and precise control of pipe weight permeter and its extrusion output, to realize the constancy of pipe weight.

◎The application of this system can shorten the start-up time, improve the producedpipe quality, and save raw material.

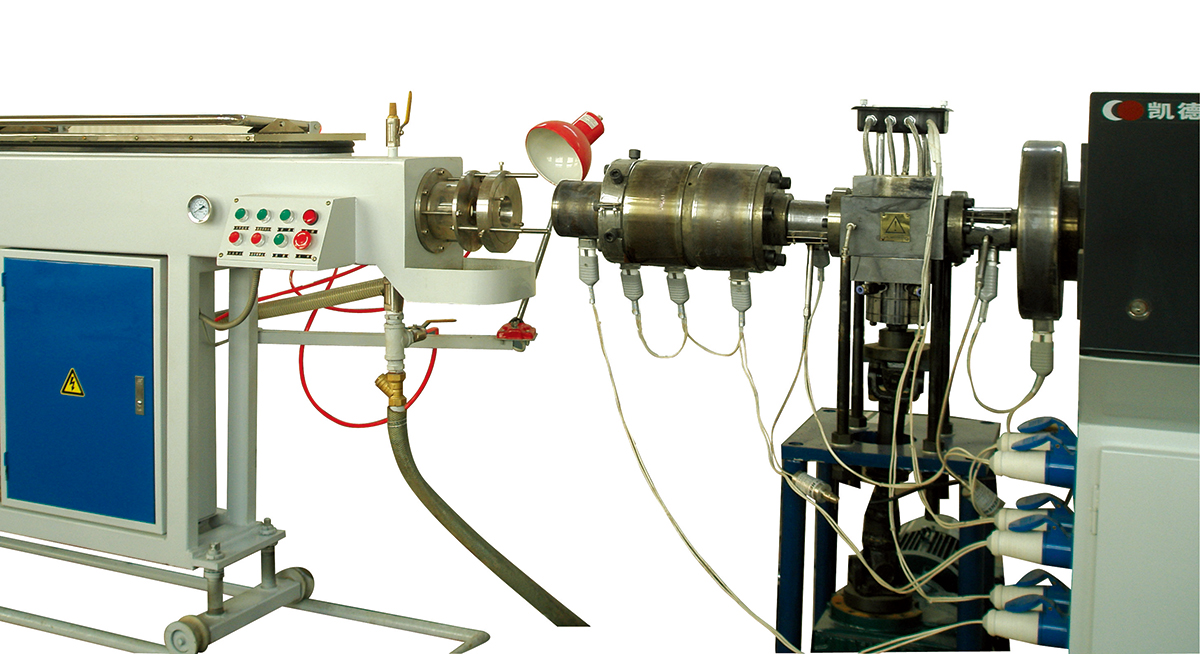

● Die Head

◎ Realize stable extrusion of PB pipe without melt pump, KAIDE is thefirst company in China, who solve this problems.

◎The application ofspecial designed spiral pressure-storage type die head ensure the high speedand constant pressure extrusion.

● Vacuum Calibrators

◎ Patented vacuum calibrators are specially designed multi-sheet waterbath type,

◎ Realize the even and effective calibrating & cooling effects.

● Haul-off Machine

◎ The PB pipe production line adopts multi-group roller clamping type belt haul-off machine, which completely avoid pipe stretching and deformation problems.

◎ The pulling speed is high and stable, without any vibrating or slipping problem.

● Other Functions

◎Added some auxiliarymachine, the PB pipe production line can produce three layers or five layers EVOH/PBpipe.