High speed HDPE pipe line adopts specially designed high efficient five-section type screw and barrel, which are our company independent design, with

completely independent intellectual property rights.

Line Model | Screw Diameter | L/D | Production Speed | Nominal Power |

SJ-75 | Ф75mm | 36:1 | 50m/min | 155KW |

SJ-60 | Ф60mm | 36:1 | 35m/min | 104KW |

SJ-80 | Ф80mm | 33:1 | 25m/min | 112KW |

SJ-65 | Ф65mm | 33:1 | 15m/min | 76KW |

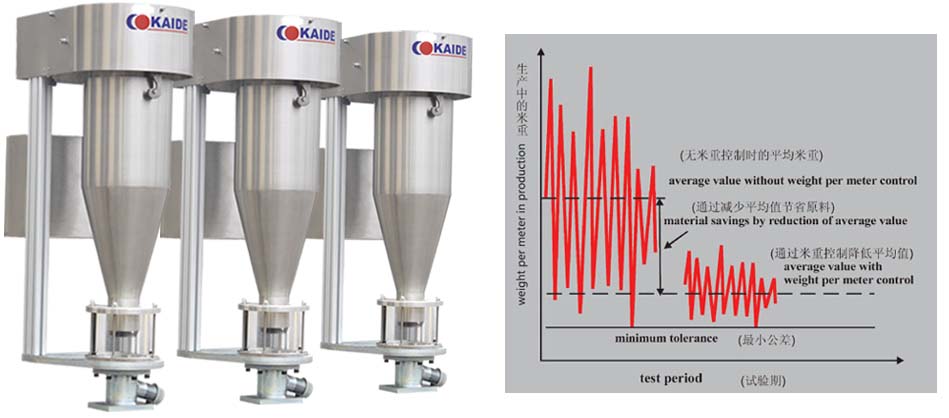

● Gravimeter System

High precise Gravimeter control systemof is applied in this HDPE pipe production line.

◎It is used for measuring &calculating and precise control of pipe weight per meter and

its extrusion output, to realize the constancy of pipe weight.

◎The application of this system canshorten the start-up time, improve the produced pipe

quality, and save raw material.

● Die Head

◎ The specially designed spiral pressure-storage die head ofthis HDPE pipe making

machine effectively overcomes the instantaneous fluctuation of extrusion pressure,

◎ Realizing high speed and constant pressure extrusion of materials.

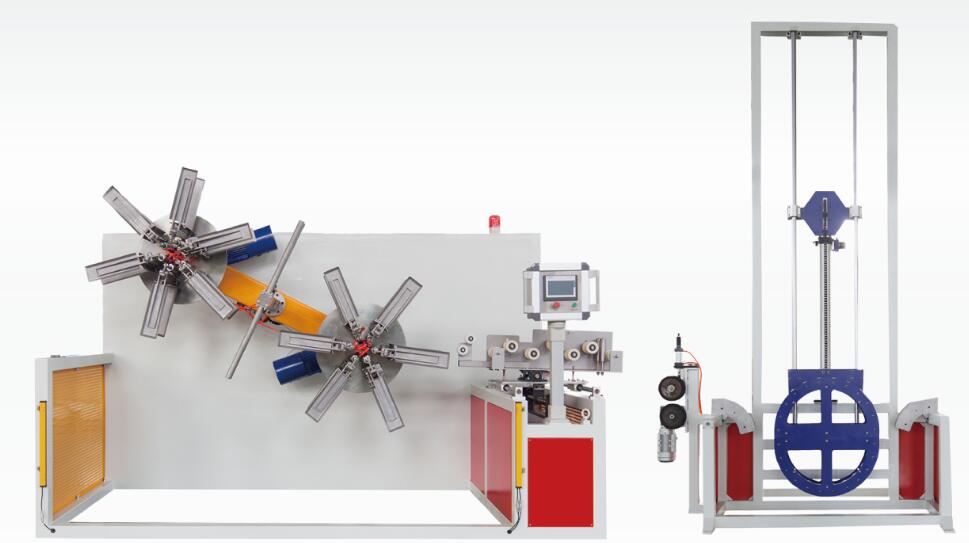

● Automatic Coiler

◎ The automatic double working position pipe coiler of this HDPE pipe machinery can

realize automatic reel changing according to set length,automatic cutting and coiling.

◎Using servo controlled high precise traversing device and tension control device.

◎ SIEMENS PLC independent control.

● Siemens PLC Control System

◎ The production line tomake HDPE pipe adopts original new generation PLC control system.

◎ Adopting Multi-point closed loop control system, ensuring high speed synchronous control and reliable operating.