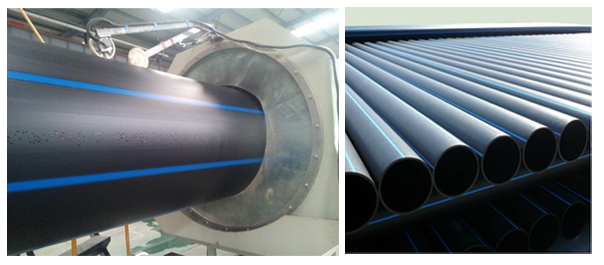

The Large-Diameter HDPE pipe line adopts specially designed high efficient five section type screw and barrel,

independently designed by KAIDE company. Which is the essential conditions for the rapid materials

plasticizing& dispersion in high output production.

Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

SJ-60 | Ф60mm | 36:1 | ф75-160mm | 1-10m/min | 145KW |

SJ-80 | Ф80mm | 33:1 | ф110-315mm | 0.8-8m/min | 186KW |

SJ-90 | Ф90mm | 33:1 | ф200-450mm | 0.2-2m/min | 250KW |

SJ-90 | Ф90mm | 36:1 | ф315-630mm | 0.2-1m/min | 442KW |

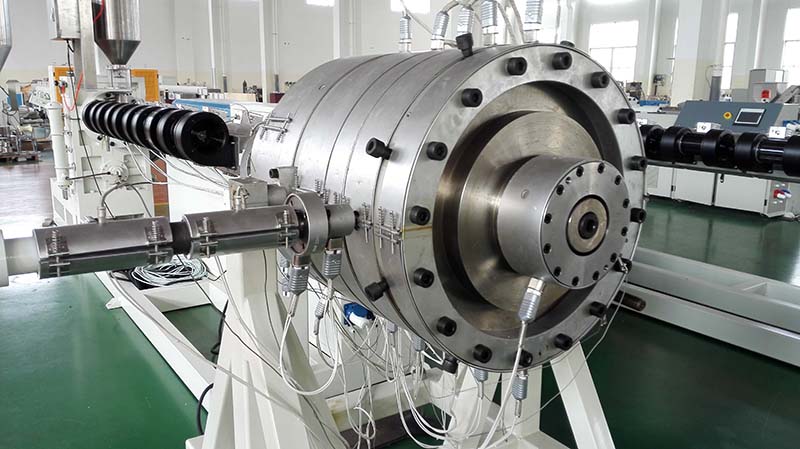

● Die Head

The HDPE pipe making machine use spiral die head, which ensures the stability of high speed

extrusion and manufactured pipe quality.

● Gravimeter System

◎ High precise Gravimeter control system is applied in this HDPE Pipe line.

◎ It is used for measuring & calculating and precise control of pipe weight per meter andits extrusion output

◎The application of this system can shorten the start-up time, improve the produced pipe quality, and

save raw material.

● PLC Control System

◎The HDPE pipe extrusion machine adopts new generation Siemens PLC programmable computer

control system,which could ensure the whole line high synchronous control and its stable &reliable running.