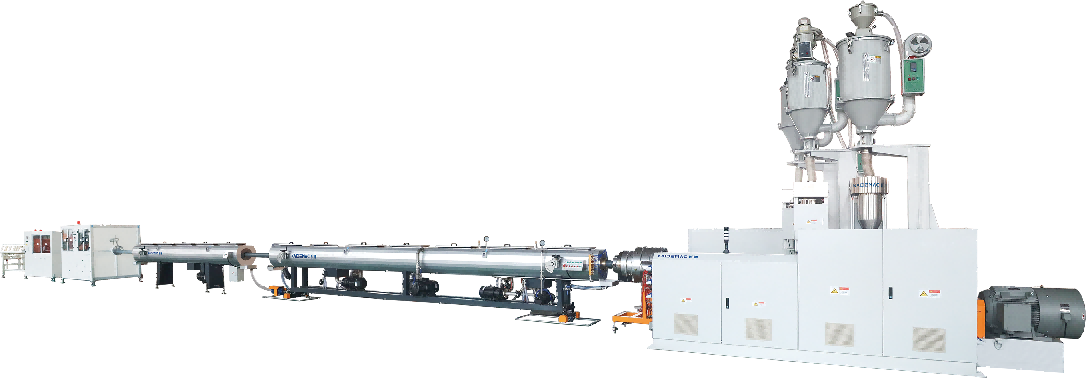

The PP super silent drainage pipe line adopts special designed high efficient extruder for viscoelastic sound-absorbing PP material, to ensure the extrusion efficiently and improve the service life of the extruder.

Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

KDJY-160 | Ф60/50/50mm | 36/33:1 | Ф50-160mm | 150kg/h | 110KW |

KDJY-200 | Ф60/65/65mm | 36/33:1 | Ф50-200mm | 165kg/h | 165KW |

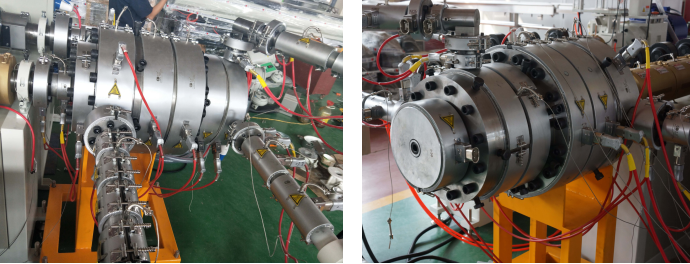

● Co-Extrusion Die Head

◎ Special designed adjustable co-extrusion die head of this PP mute pipe line is our unique patented products.

◎ Layers Distribution-10:80:10, and each layer’s thickness can be adjusted easily;

◎ Specialized Three layers spiral pressure storage composite die head, for stable and compact extrusion;

● Vacuum Calibration Tank

◎ Casing material is SS304 Stainless Steel, with special surface painting treatment for this PP drain pipe production line ;

◎ Installed Inner Pipe tray (stand) adjusted device for convenient operation.

◎ Water temperature was automatically controlled by Siemens PLC Control System

● Manufactured Pipe

◎The noise reduction of this pipe is better than cast-iron pipe, even the current market dominated UPVC drainage pipe. Indoor water dropping noise is less than 45dB.

◎It also has following advantages, such as, high resistance to bending fatigue strength, high temperature deformation resistance, aging resistance and other unique performance,

◎Being widely used at office buildings, schools, hotels, high-rise residential buildings, hospitals,nursing homes, the drainage of high temperature waste water of spa and bathplaces etc.

● PLC Control System

◎The PP soundproof drainpipe making line adopts new generation Siemens PLC programmable computer control system, which could ensure the whole line high-speed synchronous control and its stable & reliable running.