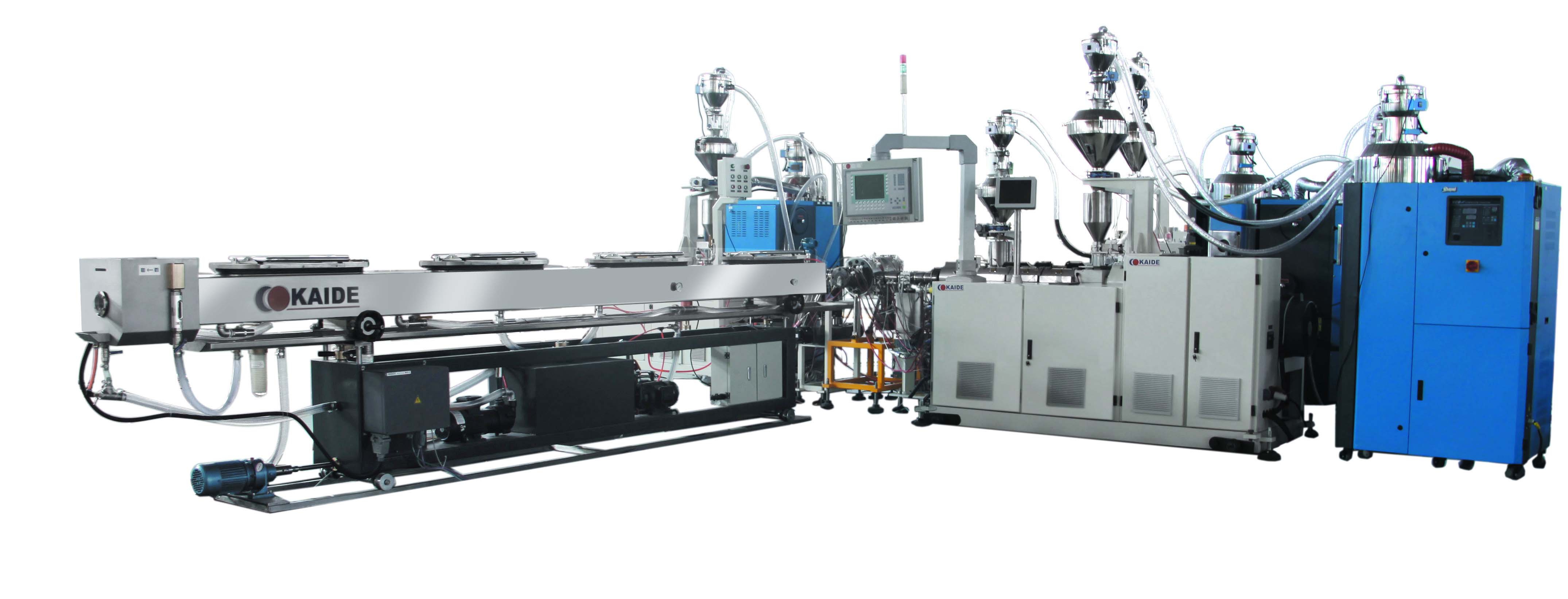

The PA Nylon pipe line adopts high efficient PA extruder, which structure isparticular designed according to PA material performance. It can extrude PA11,PA12 nylon material with high efficiency and stability.

Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

| KDFPA-45 | Ф45/45/30mm | 28:1 | Ф6-20mm | 40m/min | 101KW |

KDFPA-65 | Ф65/45/30mm | 28:1 | Ф6-20mm | 80m/min | 199KW |

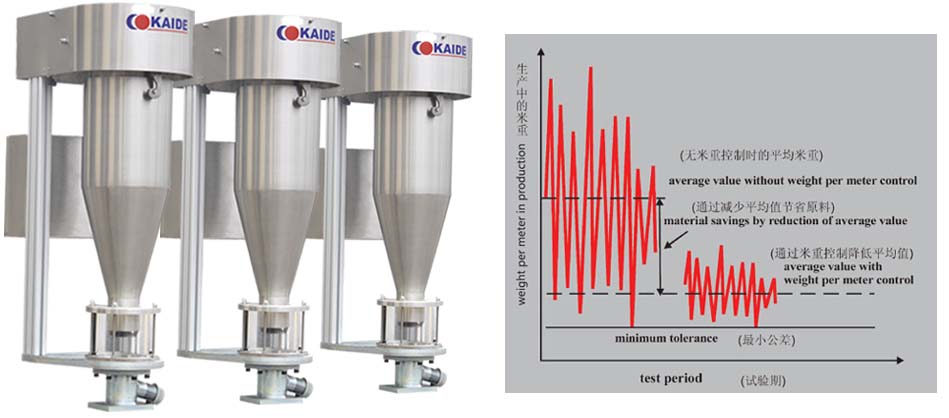

● Gravimeter System

High precise Gravimeter control system of is applied in this PA pipe production line.

◎Itis used for measuring & calculating and precise control of pipe weight permeter and its extrusion output, to realize the constancy of pipe weight.

◎Theapplication of this system can shorten the start-up time, improve the producedpipe quality, and save raw material.

● Die Head

◎Multi-layerco-extrusion die head is manufactured by high precise CNC machines.

◎Highprecision of control and extrusion achieved, ensuring each layer size of thecomposite pipe fully meet the designed requirements.

● High Precise Control System

The multi-layer PA pipe is withuniform composite, reliable bonding and bright appearance.

● PLC Control System

◎New generation of Siemens PLC programmable computer control system is adoptedin this PA pipe making machine, ensuring its high speed synchronous control and stable & reliable running.

● Production Line Series:

◎Single layer PA pipe line, three layer composite nylon alloy pipe line,and five layer EVOH/PA oxygen barrier composite pipe line.