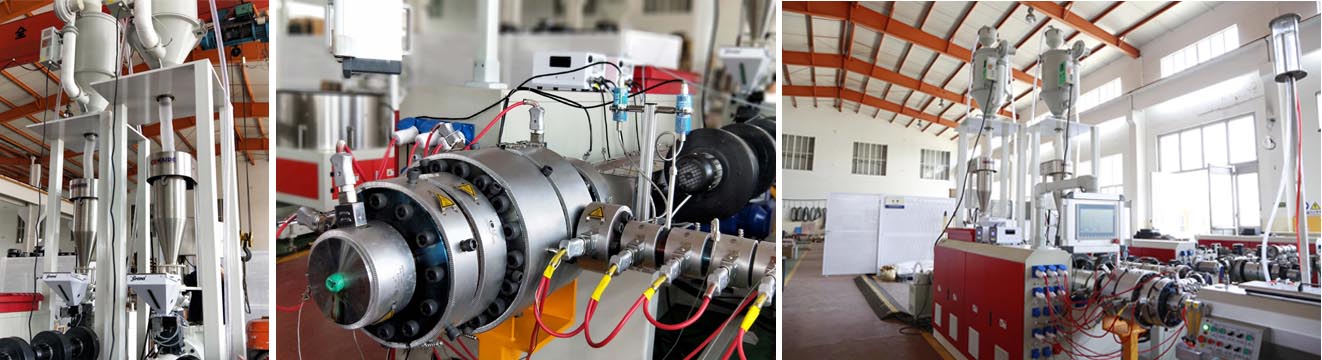

The glassfiber ppr pipe making machine adopts the specialized high efficient wear resistant extruderfor glass fiber reinforced plastic material, which ensures high speed extrusion and guarantee the long service life of extruder.

Line Model | Screw Diameter | L/D | Production Scope | Production Speed (kg/h) | Nominal Power |

KDPP-65 | ф65mm | 33:1 | ф20-110mm | 115 | 70KW |

KDPP-60 | Ф60mm | 36:1 | ф20-110mm | 230 | 102KW |

KDPP-75 | Ф75mm | 36:1 | ф20-110mm | 350 | 163KW |

KDGF-65 | ф65/45mm | 33:1 | ф20-110mm | 150 | 91KW |

KDGF-60 | ф60/65mm | 36/33:1 | ф20-110mm | 340 | 157KW |

KDGF-75 | Ф75/60mm | 36:1 | ф20-110mm | 550 | 248KW |

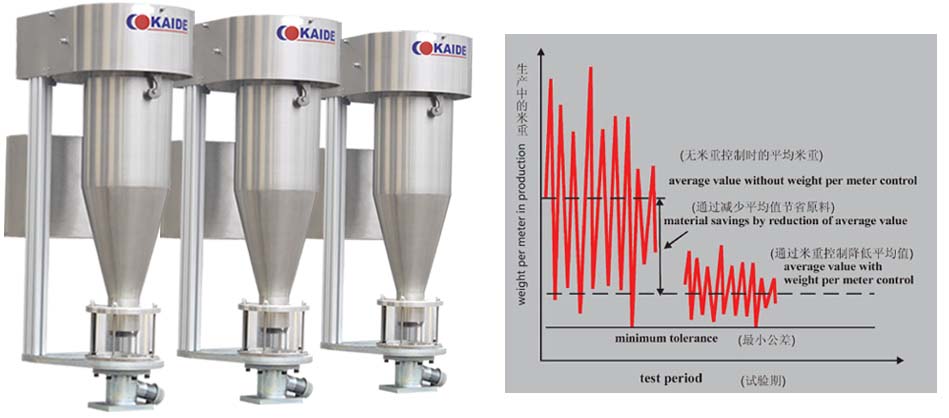

● Gravimeter System

High precise Gravimeter control system of is applied in this glassfiber PPR pipe production line.

◎It is used for measuring & calculating and precise control of pipe weight permeter and its extrusion output, to realize the constancy of pipe weight.

◎The application of this system can shorten the start-up time, improve the produced pipe quality, and save raw material.

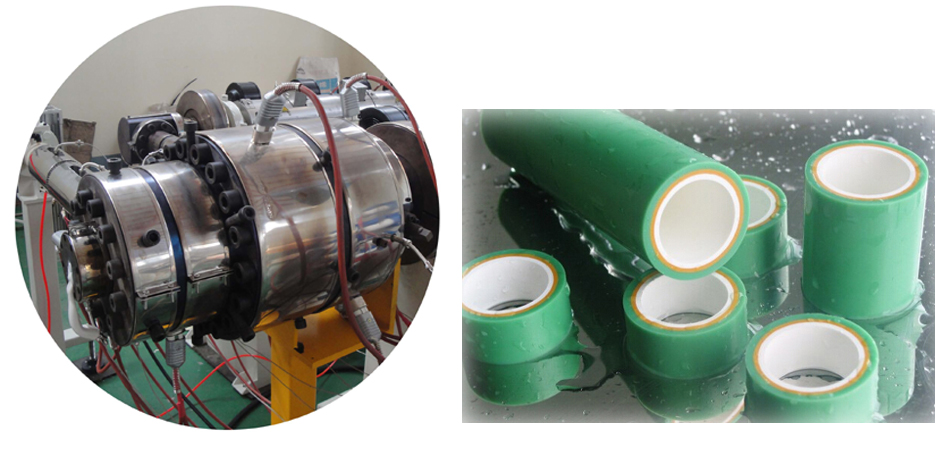

● Co-extrusion die head

◎Patented speciallydesigned adjustable co-extrusion die head, can ensure even thickness of three layers,

◎Each layer thicknesscan be adjusted freely; no need to adjust the extruder’s rotating speed.

● Haul-off machine

◎The haul-off machine adopts structure of high speed multi-group roller clamping type.

◎ Completely overcomes the vibration & skip problems in the traditional mode, ensuring high-speed stable pulling.

● PLC Control System

◎The three layers glassiber ppr pipe machinery adopts original imported new generation PLC control system.

◎Multi-point closed loop control system, which ensure the high speed synchronous control and reliable operating of the whole production line.

PPR Glassfiber Pipe Machine.pdf

PPR Glassfiber Pipe Machine.pdf