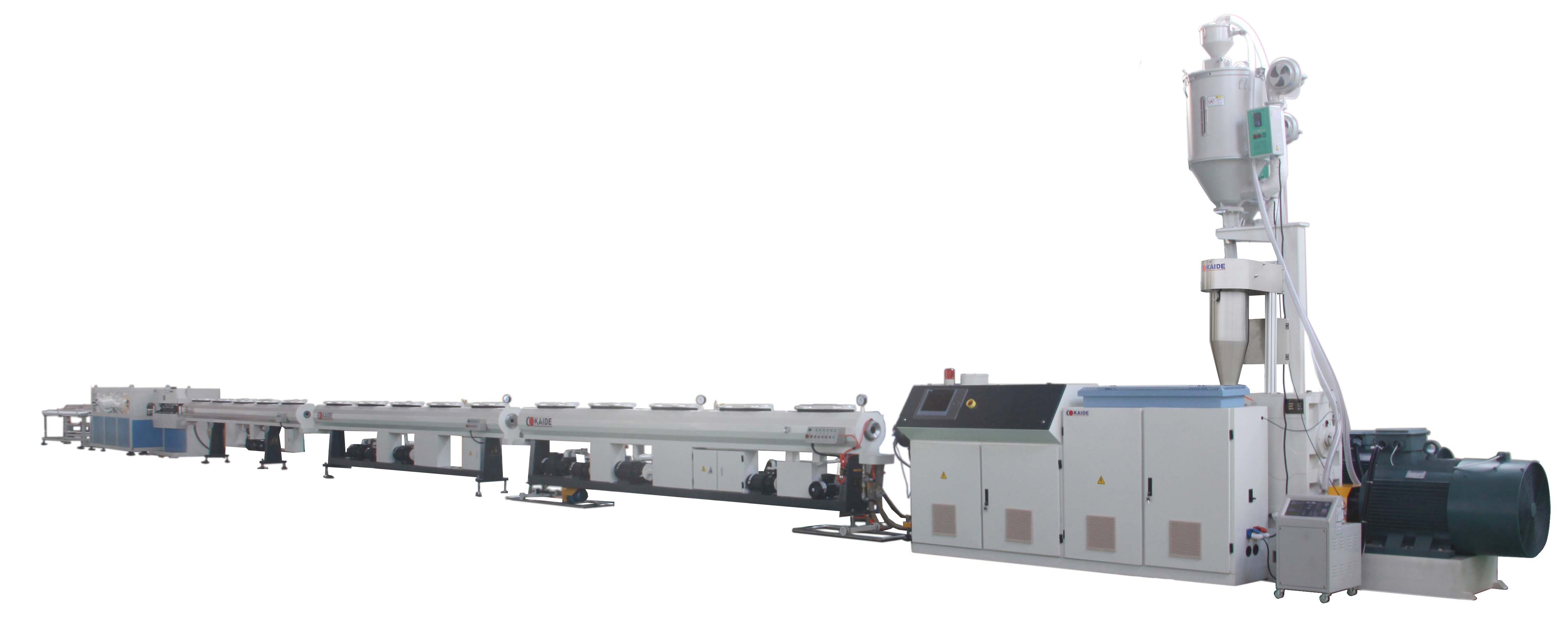

The ppr pipe making machine adopts the specialized high efficient wear-resistant extruder for ppr raw materials, which ensures high speed extrusion and guarantee the long service life of extruder.

Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

SJ-75 | ф75mm | 36/:1 | ф20-63mm | 30m/min | 198KW |

SJ-60 | Ф60mm | 36/:1 | ф20-63mm | 20m/min | 105KW |

SJ-65 | ф65mm | 33:1 | ф20-63mm | 15m/min | 68KW |

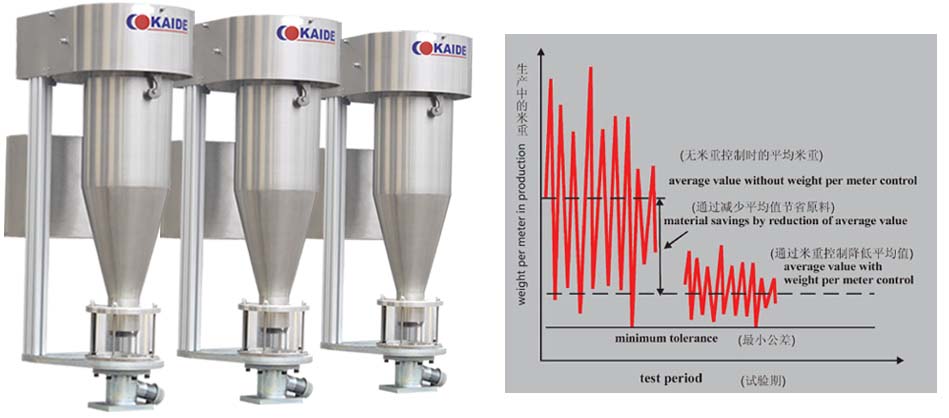

● Gravimeter System

High precise Gravimeter control system of is applied in this PPR pipe production line.

◎It is used for measuring & calculating and precise control of pipe weight permeter and its extrusion output, to realize the constancy of pipe weight.

◎The application of this system can shorten the start-up time, improve the produced pipe quality, and save raw material.

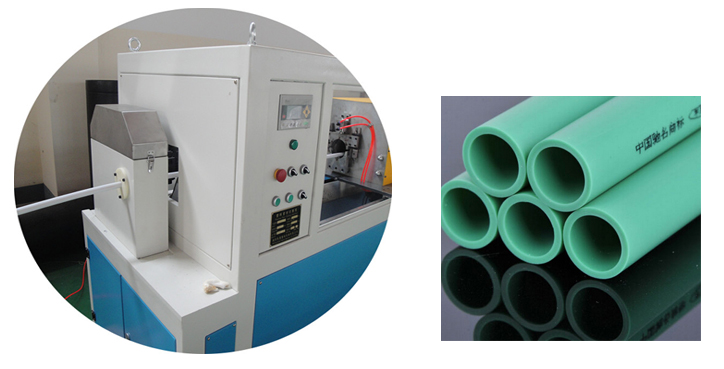

● Die head

◎ High quality material of 40Cr, long time use .

◎ Speically patented high speed calibrator is adopted for this high speed PPR pipe production line

● Haul-off machine

◎The haul-off machine adopts structure of high speed multi-group rollerclamping type.

◎ Completely overcomes the vibration & skip problems in the traditional mode, ensuring high-speed stable pulling.

● Control System

◎The high speed ppr pipe machinery adopts original imported new generation PLC control system.

◎Multi-point closed-loop control system, which ensure the high speed synchronous control and reliable operating of the whole production line.

KAIDE High Speed PPR Pipe Machine.pdf

KAIDE High Speed PPR Pipe Machine.pdf